Use it directly in Tick to set up workflows faster and with confidence.

By Mariia Novhorodtseva

28 Aug 2025

In manufacturing, even a small equipment failure can cause major delays. Regular inspections are key to safety, reliability, and efficiency. That’s why we created the Daily Equipment Inspection Checklist for manufacturing teams.

This template helps ensure every piece of equipment is checked, documented, and ready for safe operation before the shift starts.

With this checklist, teams can prevent costly breakdowns and ensure compliance with safety standards.

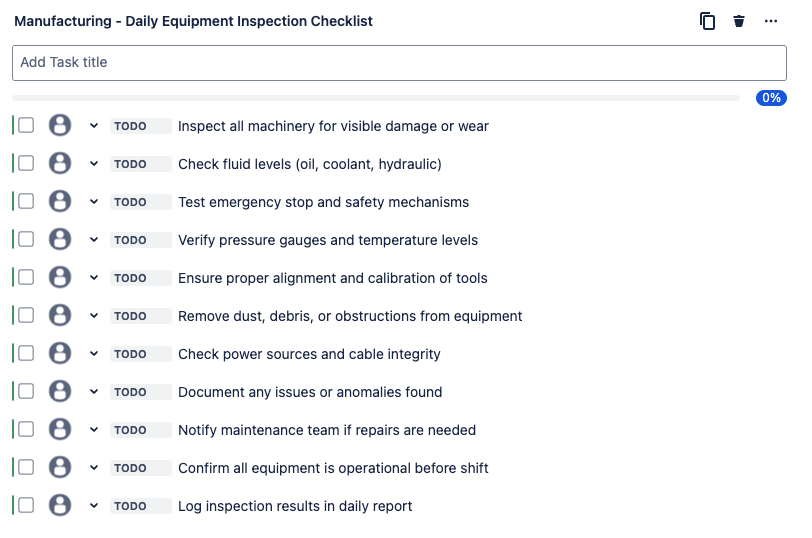

template-- Manufacturing - Daily Equipment Inspection Checklist - [ ] Inspect all machinery for visible damage or wear - [ ] Check fluid levels (oil, coolant, hydraulic) - [ ] Test emergency stop and safety mechanisms - [ ] Verify pressure gauges and temperature levels - [ ] Ensure proper alignment and calibration of tools - [ ] Remove dust, debris, or obstructions from equipment - [ ] Check power sources and cable integrity - [ ] Document any issues or anomalies found - [ ] Notify maintenance team if repairs are needed - [ ] Confirm all equipment is operational before shift - [ ] Log inspection results in daily report